Abstract

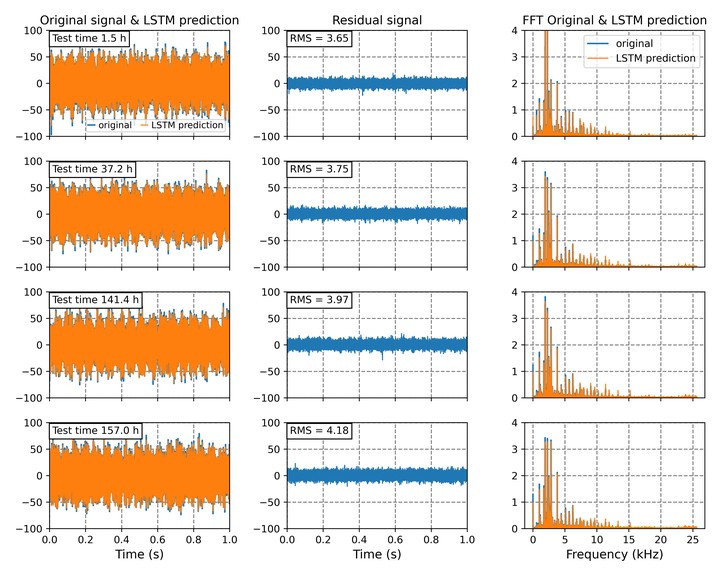

Fault detection is a critical step for machine condition monitoring and maintenance. With advances in machine learning technologies, automated faulty condition identification can be achieved by training an artificial intelligent (AI) model if sufficient data is available. In most practical applications, it is unlikely that enough data from faulty cases are available for supervised training of AI models for anomaly detection. This work is based on training data that are exclusively constituted of healthy signals (i.e., semi-supervised) and aims to develop an automated algorithm capable of identifying any abnormal mechanical behaviour captured by vibration measurements. A deep learning method with long short-term memory (LSTM) architectures combined with a one-class support vector machine (SVM) is used to separate abnormal data from normal vibration signals collected during an endurance test of a reduction gearbox and helicopter test flight data measured by multiple sensors situated at different locations of the aircraft. For the gearbox dataset, a detailed understanding of the physical mechanisms by which different types of faults (gear wear and bearing faults) affect the vibration signal led to the design of two anomaly detection architectures; i) an LSTM regression + one-class SVM for detecting new deterministic components introduced by gear faults; and ii) a two-step LSTM regression + one-class SVM for detecting new random components caused by bearing failures. For the helicopter dataset, which does not contain consecutive time-series, we show that the LSTM regression is not advantageous, and a better performance can be achieved by a simpler one-class SVM outlier detection based on statistical features. This work contributes to the field of machine condition monitoring by introducing a novel two-step LSTM configuration for removing deterministic components associated with dominant gear signals in the first step and removing the ‘residual deterministic’ components associated with varying gear signals in the second step.